MTT – Carbon-14 and Tritium Furnaces

Description

A catalyst is used to ensure complete combustion of all thermal decomposition products. These are captured for liquid scintillation assay. This technique gives greater confidence of complete combustion than ‘wet oxidation’ techniques and avoids coloured contamination of scintillation media by botanical samples. Computer control enables remote operation of multiple or individual units even in hazardous areas.

Standard features

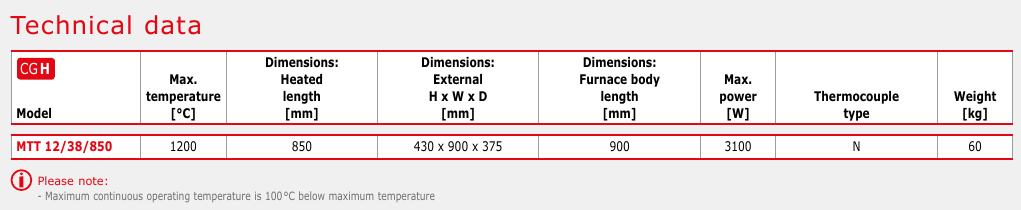

• 1200°C maximum operating temperature

• 3508P1 20 segment programmable temperature control for sample specific combustion protocols

• 2-zone tube furnace configured for capture by combustion of organically bound carbon-14 and tritium

• 2 quartz glass work tube assemblies

• 6 combustion boats

• 6 copper wire catalysts

• A comprehensive process instruction manual

• All connectors including the molecular sieve waste aerosol trap

• Eurotherm iTools allows software storage & recall of specific sample protocols

• Free from plastic or rubber components into which tritium can migrate

• Large sample capacity up to 20 ml provides accurate determinations

• Originally developed in partnership with AEA Technology

• Over-temperature protection of both heated zones

• RS485 communications & control

• Three sets of glass gas bubblers (12 in total)

• Unique catalyst optimisation manifold

Options (specify these at time of order)

• Additional sets of bubblers (sets of 4)

• Additional sets of combustion boats (sets of 6)

• Additional work tubes

• Additional copper catalyst (sets of 3)

Order now

To make your order, please contact us at info@polyscientific.com.my or call us at +6 06 3350 690