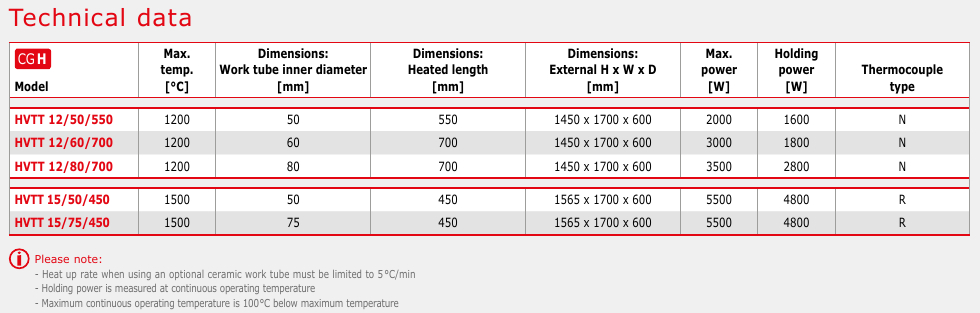

The HVTT high vacuum turbo-molecular tube furnaces at 1200°C are available in three standard sizes with a range of tube lengths and diameters available.

HVTT – High Vacuum Tube Furnaces

Description

The HVTT high vacuum tube furnaces at 1500°C are available with two work tube diameters. These units are often the starting point for additional customisation such as automated control of gate valves, gas purge, back-fill systems and co-ordinated control of roughing pump with the turbo-molecular high vacuum pump.

Standard features

• 1200°C & 1500°C maximum operating temperature

• All controls are mounted within the base unit

• Access to the work tube is via a removable stainless steel vacuum flange

• Carbolite Gero 301 digital PID controller with single ramp to set point and process timer

• Capable of 10-5 mbar vacuum in a clean empty work tube

• Cooling water failure alarm

• Heated lengths of 450, 550 or 700 mm

• Manually operated roughing / backing valve

• Penning gauge high vacuum monitor

• Pirani gauge low vacuum monitor

• Radiation shields at both ends of the work tube maintain uniformity without reducing pump speeds

• Supplied with work tube inner diameters of 50, 60, 80 mm (HVTT 1200) and 50 and 75 mm (HVTT 1500)

• Vacuum provided by oil-free scroll pump & turbo-molecular pump

• Work tube connects to the vacuum system via stainless steel connection

Options (specify these at time of order)

• A range of sophisticated digital controllers, multi- segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications

• Custom built models including a variety of gas backfill systems, automatic & semi-automatic vacuum systems and 3-zone control for improved uniformity is available

• Over-temperature protection (recommended to protect valuable contents & for unattended operation)

Order now

To make your order, please contact us at info@polyscientific.com.my or call us at +6 06 3350 690