The HTR furnaces combine in a laboratory scale unit many of the advantages of a fluidised bed reactor with those of a rotary kiln.

HTR – Rotary Reactor Tube Furnaces

Description

The sample is simultaneously heated and mixed under a controlled atmosphere. This overcomes the longer reaction times required in standard chamber or tube furnaces.

Standard features

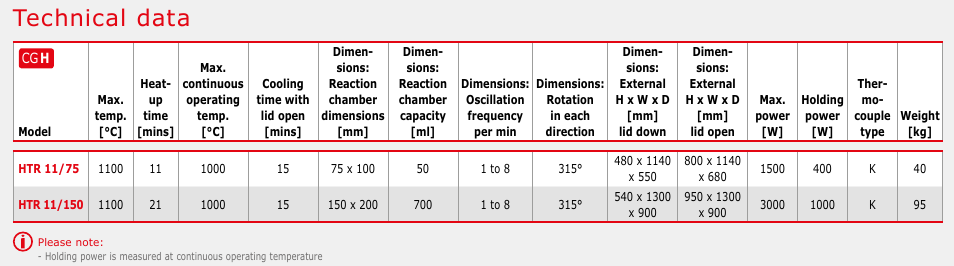

• 1100°C maximum operating temperature

• A 30 mm flow meter for nitrogen is provided

• A positive break safety interlock switch cuts power to the elements when the heating chamber is open

• A single seal gasket directs the reactor exhaust into a removable stainless steel exhaust box from where a gas outlet allows piping to an extraction system

• Carbolite Gero 301 PID controller with single ramp to setpoint and process timer

• Developed in partnership with the Imperial College of Science & Technology, London

• Gas enters the reactor through a flexible silicon rubber tube

• Heating is provided by long life, rapid heating, resistance wire elements mounted in rigid, half cylindrical vacuum formed insulation modules

• Quartz reaction vessel included as standard

• The fluted internal surface of the quartz reactor ensures thorough mixing as the variable speed electric drive system oscillates the reactor tube through 315°

Options (specify these at time of order)

• A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications

• Over-temperature protection (recommended to protect valuable contents & for unattended operation)

• Optional inconel reactor

• Single or multiple flow meters for different gases

Order now

To make your order, please contact us at info@polyscientific.com.my or call us at +6 06 3350 690