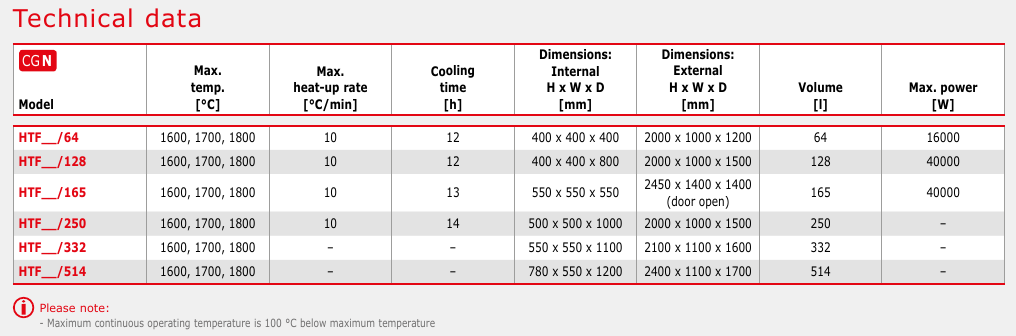

HTF – High Temperature Industrial Chamber Furnaces

Description

Independent over-temperature protection is fitted as standard for unattended operation. If debinding is required before sintering, Carbolite Gero offers a debinding package for the HTF. The debinding package consists of an inlet for preheated air, several gas inlets, and an afterburner. The preheated air is simultaneously purged through several gas inlets which improves temperature uniformity at low temperatures and envelops the sample in the incoming air. All gaseous by-products generated during the debinding process are burnt in an afterburner that is driven by propane gas and compressed air. On completion of debinding, the furnace temperature will increase to begin the sintering process.

Standard Features

• 1600°C, 1700°C & 1800°C maximum operating temperatures

• Advanced refractory interior, used in combination with energy efficient low thermal mass insulation

• From 64 to 514 litre capacities

• High quality molybdenum disilicide heating elements

• Over-temperature protection

• Programmable 3216P1 controller

• Side hinged door

Options (specify these at time of order)

• A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications

Please note that special controllers may be needed for this model

• Debinding in air with the debinding package

• Gas supply with manually adjustable flow meter is available

• Modification of the atmosphere in the furnace chamber can be achieved but oxygen cannot be removed completely because it is not gas tight

• Up and away parallel opening door

Order now

To make your order, please contact us at info@polyscientific.com.my or call us at +6 06 3350 690