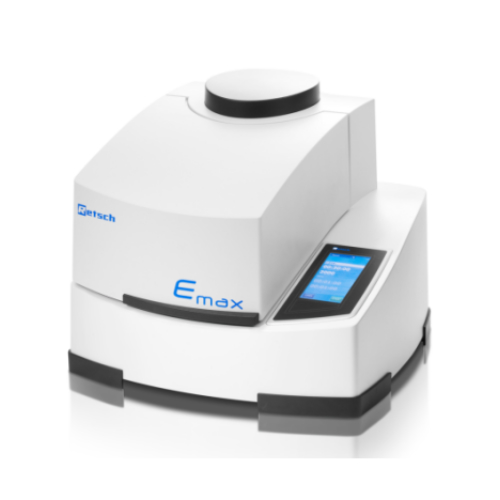

The Emax is an entirely new type of ball mill for high energy milling.

High Energy Ball Mill Emax

Description

The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time.

The high energy input is a result of an unrivaled speed of 2000 min-1 and the optimized jar design. Thanks to the revolutionary cooling system with water, the high energy input is effectively used for the grinding process without overheating the sample. Due to the special grinding jar geometry, the sample is thoroughly mixed which results in a narrow particle size distribution.

Unlike other high energy ball mills, the Emax is capable of continuous grinding operation without interruptions for cooling down. This dramatically reduces the grinding time. The high energy input in combination with the unique cooling system provides perfect conditions for effective mechanical alloying or grinding down to the nanometer range.

A wealth of safety features such as the integrated safety closure of the grinding jar, temperature control with automatic start/stop system, and integrated imbalance controls make operation of the bench-top mill Emax very user-friendly.

Application Examples :

• alloys, bones, carbon fibres, catalysts, cellulose, cement clinker, ceramics, chemical products, clay minerals, coal, coke, concrete, fibres, glass, gypsum,

iron ore, kaolin, limestone, metal oxides, minerals, ores, paper, pigments, plant materials, polymers, quartz, semi-precious stones, sewage sludge, slag,

soils, tea, tobacco, waste samples, wood, … continue to application database

Product Advantages :

• Easy installation of grinding jars

• Easy operation via touch screen, 10 SOPs storable

• Faster and finer grinding than any other ball mill

• Jars with integrated safety closure

• Narrow particle size distribution thanks to special jar design which improves mixing of the sample

• Operation with 2 grinding jars

• Patented drive concept

• Range of jar materials allow for contamination free grinding

• Speed of 2000 min-1 allow for ultra-fast pulverization of the sample

• Temperature-controlled grinding

• Water cooling permits continuous operation without cool down breaks

Features :

| Applications : | nano grinding, size reduction, homogenizing, mechanical alloying, colloidal milling, high energy comminution |

| Field of application : | agriculture, biology, Chemistry, construction materials, engineering / electronics, environment / recycling, geology / metallurgy, glass / ceramics, medicine /

pharmaceuticals |

| Feed material : | medium-hard, hard, brittle, fibrous – dry or wet |

| Size reduction principle : | impact, friction |

| Material feed size* : | < 5 mm |

| Final fineness* : | < 80 nm |

| Batch size / feed quantity* : | max. 2 x 45 ml |

| Speed at 50 Hz (60 Hz) : | 300 – 2000 min-1 |

| Cooling : | controlled integrated water cooling / option: external chiller |

| Temperature control : | yes (min and max temperature may be defined) |

| No. of grinding stations : | 2 |

| Type of grinding jars : | with integrated safety closure devices |

| Material of grinding tools : | stainless steel, tungsten carbide, zirconium oxide |

| Grinding jar sizes : | 50 ml / 125 ml |

| Setting of grinding time : | 00:01:00 to 99:59:59 |

| Interval operation : | yes, with optional direction reversal |

| Interval time : | 00:01:00 to 99:59:59 |

| Pause time : | 00:01:00 to 99:59:59 |

| Storable SOPs : | 10 |

| Interface : | USB / LAN ( RJ45) |

| Drive : | 3-phase asynchronous motor with frequency converter |

| Drive power : | 2600 W |

| Electrical supply data : | different voltages |

| Power connection : | 1-phase |

| Protection code : | IP 30 |

| Power consumption : | ~ 3100W (VA) |

| W x H x D closed : | 625 x 525 x 645 mm |

| Net weight : | ~ 120 kg |

| Standards : | CE |

| Patent / Utility patent : | Inclined Grinding bowls (US 8,042,754 B2) |

Please Note:

*depending on feed material and instrument configuration/settings

Order now

To make your order, please contact us at info@polyscientific.com.my or call us at +6 06 3350 690