The GLO features a vacuum tight retort with symmetrical positioning of the heating elements. The heating elements are made of CrFeAl, also known as APM, and are embedded in ceramic fibre insulation.

GLO – Annealing Furnaces

Description

The GLO furnaces have a compact, space saving design. They are often equipped with an optional vacuum pumping system to reduce the oxygen levels prior to heat treatment. To ensure the lowest possible contamination levels, several cycles of vacuum and nitrogen purging can take place to create a pure atmosphere in the retort. Vacuum assisted cycling is far superior to a simple flow of nitrogen through the retort as the process creates a pure atmosphere faster and requires less nitrogen. After oxygen levels have been reduced heat treatment begins under an inert atmosphere with a slight overpressure.

The front door of the cylindrical retort can be heated if required. The purge gas enters the retort via the water cooled front door and is preheated by the radiation shields, which are located at the front of the chamber. The GLO is provided with a rear port for the expulsion of any gaseous by-products generated during the process. The GLO can be operated manually or with the use of the optional automated system.

The furnace may be operated with reactive gases such as hydrogen, which requires appropriate optional safety technology. The hydrogen safety system includes an automatic operating system with a nitrogen purging tank to detect and purge the system should any malfunctions be detected. All devices are SIL2 certified.

The optional debinding package allows debinding or pyrolysis processes to be carried out. Virtually no condensation occurs as the unit is equipped with an afterburner and heated gas outlet for strong outgassing applications. The GLO can be equipped with an optional fast cooling system. The retort can be air cooled from the outside or purged with cold, inert gas.

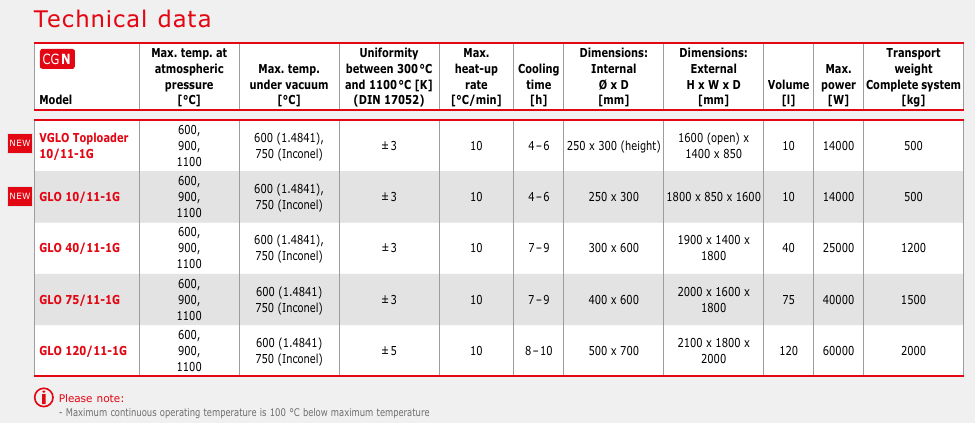

The maximum temperature of the GLO is 1100°C. In this temperature range, heat is transmitted via a high amount of heat convection and conduction. To ensure excellent temperature uniformity, the GLO can optionally be equipped with a gas circulation system by means of a fan located at the rear of the furnace, which ensures that the sample is surrounded by uniform inert gas at all times. The sample specimen is placed on an optional, horizontal charging rack with the incoming gases guided across the sample. Any gaseous by-products generated are immediately flushed out of the furnace. An optional probe thermocouple can be positioned at the rear of the furnace and in close proximity to the samples. The probe thermocouple may serve as the cascade thermocouple for the two heating zones of the GLO, and simultaneously, monitors the temperature directly at the sample. The heating elements are located outside the retort. An optional over-temperature thermocouple is used for unattended operation. Further thermocouple probes may be integrated into the retort upon request.

Standard features

• Gas control with manual control for a single inert gas, air or formation gas

• Gas tight retort made of 1.4841 (equals grade 314) stainless steel for highest vacuum possible

• Manual control

• Precisely controlled atmosphere with highest possible purity

• Radiation shields

• Two heating zones

• Water cooled door with gas tight rubber sealing (water cooling must be provided at customer site)

Options (specify these at time of order)

• A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications

Please note that special controllers may be needed for this model

• Charging racks

• Complete automation using Siemens SPS control with touch panel and mass flow controller for the gases

• Controls for multiple gases

• Debinding package with propane gas fired afterburner

• Fan inside the retort for better uniformity at lower temperatures

• Fast cooling system

• Gas packages for explosive or dangerous gases e. g. pure hydrogen with comprehensive safety features

• Heated front door

• Heated gas outlet

• Other retort sizes on request

• Other retort material e. g. Inconel or quartz glass

• Over-temperature protection (recommended to protect valuable contents & for unattended operation)

• Vacuum pumps

• Water cooled coolings traps for volatile chemicals

• Water chiller for water cooling system if cooling water is not available at customer site

Order now

To make your order, please contact us at info@polyscientific.com.my or call us at +6 06 3350 690