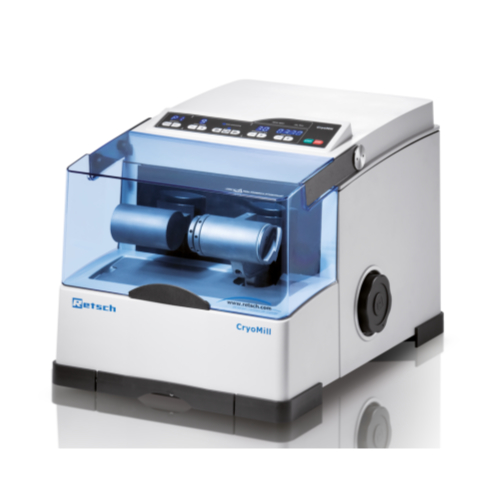

The CryoMill is tailored for cryogenic grinding.

CryoMill

Description

The grinding jar is continually cooled with liquid nitrogen from the integrated cooling system before and during the grinding process.

Thus the sample is embrittled and volatile components are preserved. The liquid nitrogen circulates through the system and is continually replenished from an Autofill system in the exact amount which is required to keep the temperature at -196 °C.

Powerful impact ball milling results in a perfect grinding efficiency. The Autofill system avoids direct contact with LN2 and makes cryogenic grinding very safe. Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 ml.

Application Examples :

• animal feed, bones, chemical products, food, hair, oil seeds, paper, plant materials, plastics, sewage sludge, soils, tablets, textiles, tissue, waste samples,

wood, wool, … continue to application database

Product Advantages :

• 3 different grinding modes (cryogenic, dry or wet at ambient temperature)

• Ceramic jar available

• Clearly structured user interface, memory for 9 SOPs

• Closed LN2-system (autofill) for enhanced safety, avoids any contact of the user with LN2

• Low LN2-consumption

• Powerful cryogenic grinding by impact and friction, up to 30 Hz

• Programmable cooling and grinding cycles (10 s to 99 min)

• Screw-top grinding jars for convenient, leak-proof operation

• Wide range of accessories including various LN2 feeding systems, jar and ball sizes, adapter racks, materials

Features :

| Applications : | size reduction, mixing, homogenization, cell disruption |

| Field of application : | agriculture, biology, chemistry / plastics, construction materials, engineering / electronics, environment / recycling, food, geology /

metallurgy, glass / ceramics, medicine / pharmaceuticals |

| Feed material : | hard, medium-hard, soft, brittle, elastic, fibrous |

| Size reduction

principle : |

impact, friction |

| Material feed size* : | ≤ 8 mm |

| Final fineness* : | ~ 5 µm |

| Batch size / feed

quantity* : |

max. 20 ml |

| No. of grinding

stations : |

1 |

| Setting of

vibrational frequency : |

digital, 5 – 30 Hz (300 – 1800 min-1) |

| Typical mean

grinding time : |

10 min / 4 min (cooling / grinding) |

| Dry grinding : | yes |

| Wet grinding : | yes |

| Cryogenic grinding : | yes |

| Cell disruption with

reaction vials : |

yes |

| Self-centering

clamping device : |

yes |

| Type of grinding jars : | screw top design |

| Material of

grinding tools : |

hardened steel, stainless steel, zirconium oxide, PTFE |

| Grinding jar sizes : | 5 ml / 10ml / 25 ml / 35 ml / 50 ml |

| Autofill : | 50 l |

| Setting of grinding time : | digital, 30 s – 99 min |

| Storable SOPs : | 9 |

| Electrical supply data : | 100-240 V, 50/60 Hz |

| Power connection : | 1-phase |

| Protection code : | IP 30 |

| Power consumption : | 260 W |

| W x H x D closed : | 395 x 373 x 577 mm (D: 710 mm with exhaust tube) |

| Net weight : | ~ 45 kg |

| Standards : | CE |

Please Note:

*depending on feed material and instrument configuration/settings