BLF bottom loading furnaces use an electrically operated elevator hearth, which as it rises into the furnace chamber, lifts the load into the heated zone.

BLF – High Temperature Bottom Loading Furnaces

Description

This furnace provides the following advantages: easy loading of samples and uniform heating achieved by locating elements in all six side walls of the chamber.

Standard Features

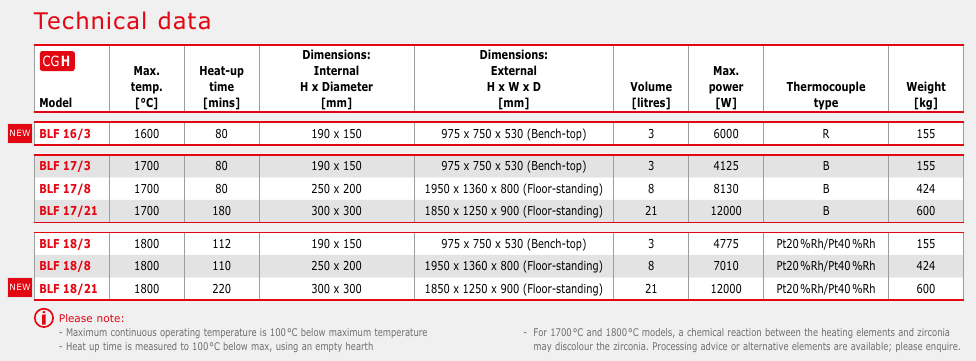

• 1600°C, 1700°C & 1800°C maximum operating temperature

• 3 to 21 litre capacities

• 1600°C model heated by silicon carbide elements

• 1700°C & 1800°C models heated by molybdenum disilicide elements

• Excellent temperature uniformity as a result of the hexagonal chamber

• Electrically operated elevator hearth protects operator from the chamber’s radiant heat

• Hearth cage with safety interlock

• Ideal for: sintering high performance ceramics, melting glass under high temperature or working with modified atmospheres

• Over-temperature protection to protect load or furnace during unattended operation

• Programmable 3216P1 controller

• Rapid heating & cooling cycles can be achieved through raising & lowering the hearth

Options (specify these at time of order)

• A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications

• Compatible crucibles

• Customised options including: adaptation to introduce thermocouple or stirrer through the chamber roof and rotating hearth

• Modified hearth for the introduction of gases into an inverted crucible (not gas tight)

• Plasma sprayed alumina protection tube to protect heating elements from sample contamination

• Radiation shutter

Order now

To make your order, please contact us at info@polyscientific.com.my or call us at +6 06 3350 690