The range of AAF ashing furnaces is designed specifically to provide optimum ashing conditions to ensure complete combustion of the sample.

AAF – Standard Ashing Furnaces

Description

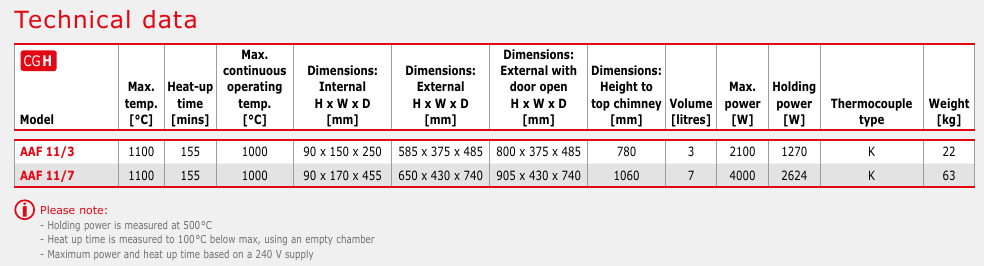

The AAF 11/3 & AAF 11/7 ashing furnaces provide a continuous flow of preheated air through the chamber, and are designed to comply with ISO 1171:2010, ASTM D3174-04: 2010 and ASTM D4422.

Standard features

• 1100°C maximum operating temperature

• 4 sided heating (2 sides, roof & hearth)

• Air inlet & tall chimney give airflow of 4 to 5 changes per minute

• Carbolite Gero 301 single ramp to setpoint & process timer

• Designed to comply with ISO 1171:2010, ASTM D3174-04: 2010 and ASTM D4422

• Ideal for ashing foods, plastics, coal & other hydrocarbon materials

• Large floor area allows for large number of samples

• Low chamber height holds airflow close to samples for optimum combustion

• Powerful elements with graded winding compensate for heat loss due to high airflow

• Preheating of air before it enters the chamber gives excellent uniformity

• Wire elements are protected from chemical & mechanical damage by a hard wearing alumina based liner

Options (specify these at time of order)

• 2 phase electrical supply for AAF 11/7

• A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications

• Over-temperature protection (recommended to protect valuable contents & for unattended operation)

Order now

To make your order, please contact us at info@polyscientific.com.my or call us at +6 06 3350 690